A brief introduction to runlian lenses

Shenzhen Runlian Plastic Mold Co., Ltd. is a professional enterprise specializing in the design, manufacturing, and injection molding production of optical precision molds. Established in 2012, the company boasts an experienced team of optical design and mold manufacturing R&D professionals capable of efficiently developing LED lenses tailored to various angles, light patterns, and mixed light functions, providing customers with professional optical product technical solutions.

1. Comprehensive product portfolio and market response mechanism

Covering all aspects of LED lighting, including indoor lighting, outdoor lighting, automotive lighting, streetlights, commercial engineering lighting, stage lighting, floodlights, wall-washing lights, ground-recessed lights, TV backlights, and other applications; Product types include: streetlight lenses, wall-washing light lenses, floodlight lenses, backlight lenses, ground-recessed light lenses, 2835, 3030, 3535, 5050, 5630, 5730, surface-mounted lenses, COB light guides, etc.

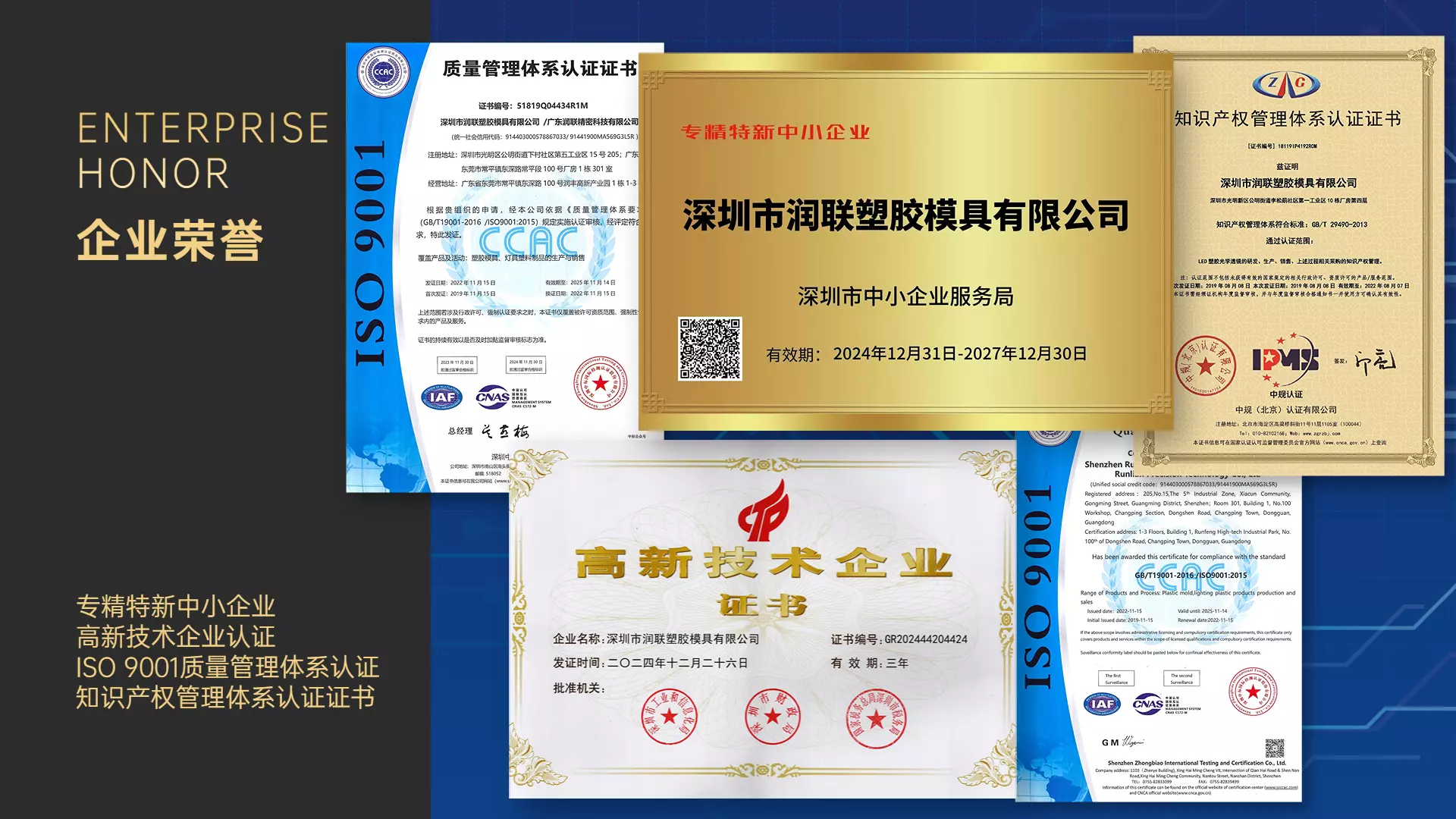

2. Strict Quality Control and Industry Certification

Production standards: Advanced production equipment, using Japanese-imported Mitsubishi PMMA material and Japanese-imported optical-grade PC material, ensuring the highest level of reliability for product quality and light transmission. The light transmission rate of all lenses exceeds 90%.

Industry certifications: Obtained the “High-Tech Enterprise Certification” and “Specialized, Refined, and Innovative SME” certifications; passed the “ISO 9001 Quality Management System Certification” and obtained the “Intellectual Property Management System Certification Certificate.” Equipped with the industry's most advanced optical measurement equipment to meet optical lens measurement requirements.

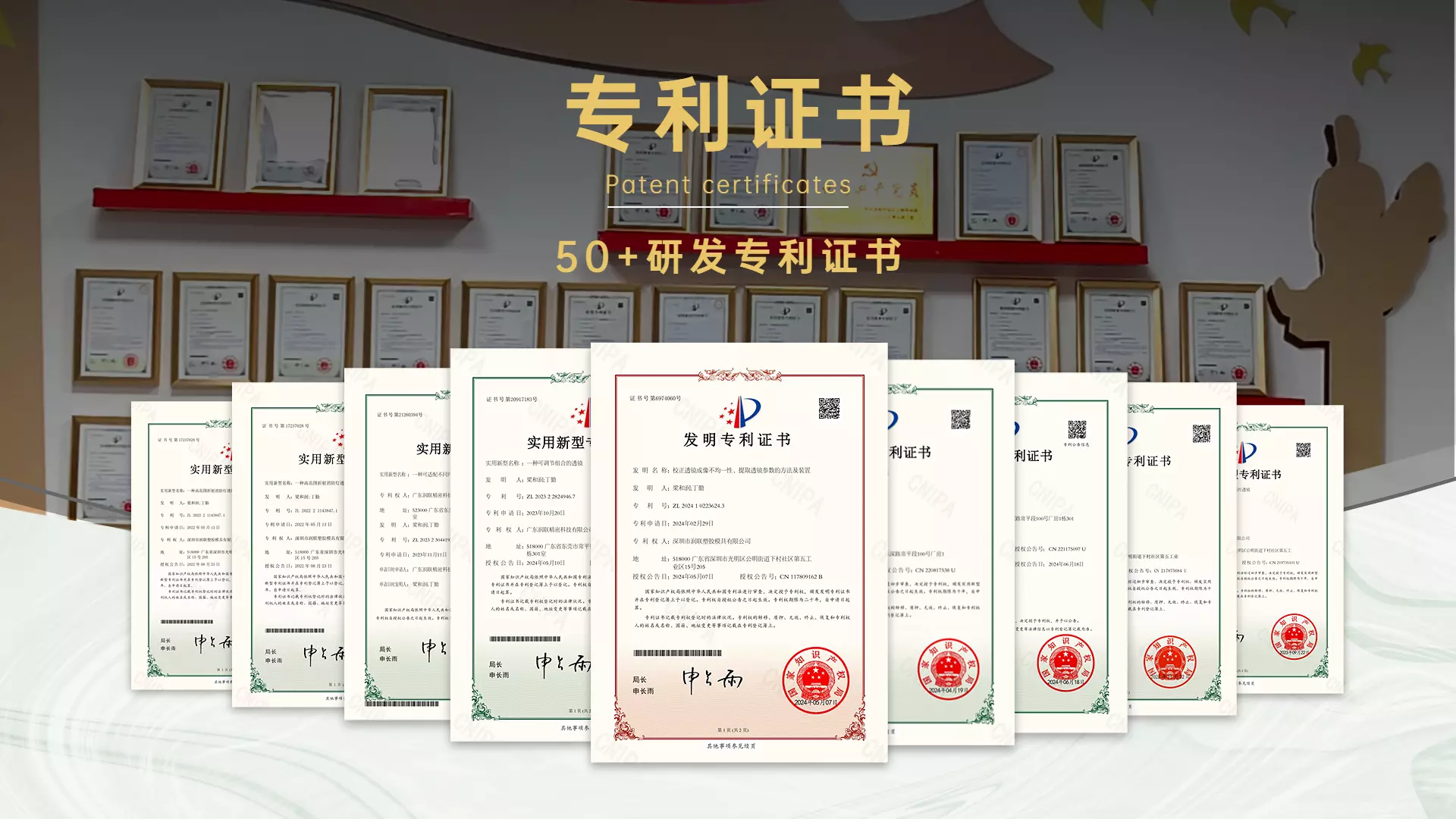

3. Cutting-Edge Technology R&D and Patent Fortress Construction

Runlian has a factory area of 12,000 square meters, with 80 injection molding machines (imported + domestic), 16 mold manufacturing machines, 8 CNC machining centers, and 12 wire cutting machines. The company has a team of 25 highly skilled professionals specializing in optical design, mold manufacturing, and injection molding production; this is a team with extensive experience in optical design and mold manufacturing R&D.

Team Advantages: Optical R&D Team + Quality Control Team + Precision Mold Manufacturing Team. The team can efficiently develop LED lenses that meet various angle, light pattern, and mixed light functionality requirements, enabling lighting fixtures to achieve maximum luminous efficiency and optimal lighting effects.

Patent Certificates: The company has obtained over 50 product patent certificates, establishing a reputation for exceptional product performance.

4. Customized Services

5. Market Recognition and Industry Collaboration

Application Cases: Products have been successfully applied in indoor lighting, outdoor lighting, commercial engineering lighting, advertising light boxes, and other fields, with customers spanning Europe, the Middle East, Japan, South Korea, and domestic markets.

Strategic Partners: